I. Installation of Set Screw Pillow Block Bearings:

- Check Shaft Accuracy: Before installing the bearing, check whether the shaft’s dimensional tolerance is qualified. Ensure that the shaft is free of bends, dents, burrs, and other defects. Apply some lubricant to the shaft as well.

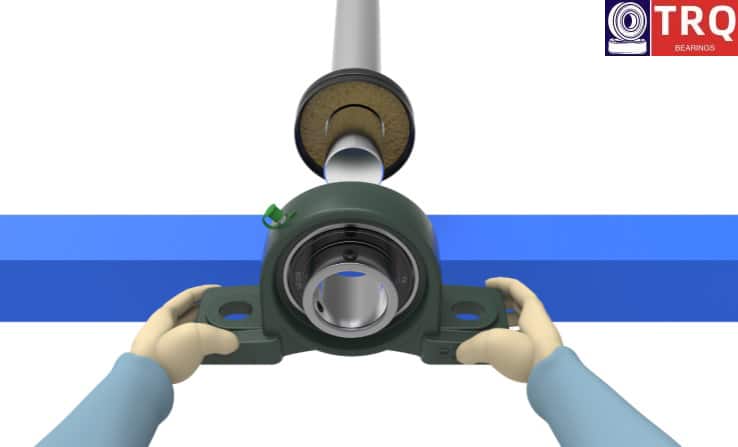

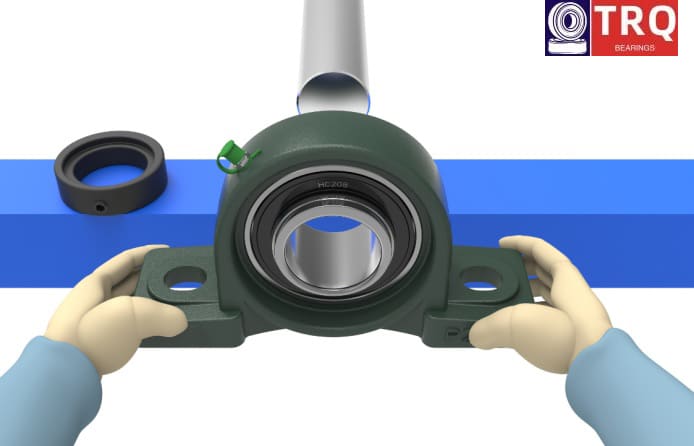

- Install pillow block bearing : Avoid using metal objects like hammers to strike the bearing during installation. This is particularly important for bearings with retaining ring seals, as striking the bearing could cause the retaining ring to shift inward and contact the inner seal, leading to friction during operation. This may result in poor rotation or a significant temperature increase, potentially damaging the bearing. If the bearing bore fits tightly with the shaft, it is recommended to use a press to install it by pressing on the inner ring end face.

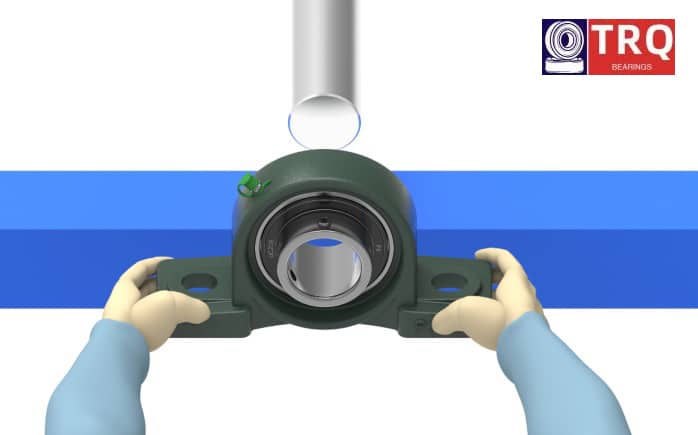

Pre-tighten the Bearing Housing: Excessive tightening torque on the bolts may deform the bearing housing. Use the appropriate tightening torque to secure the bolts. TRQ recommends using washers with the bolts when installing the bearing housing, as using bolts alone may damage the bearing housing.

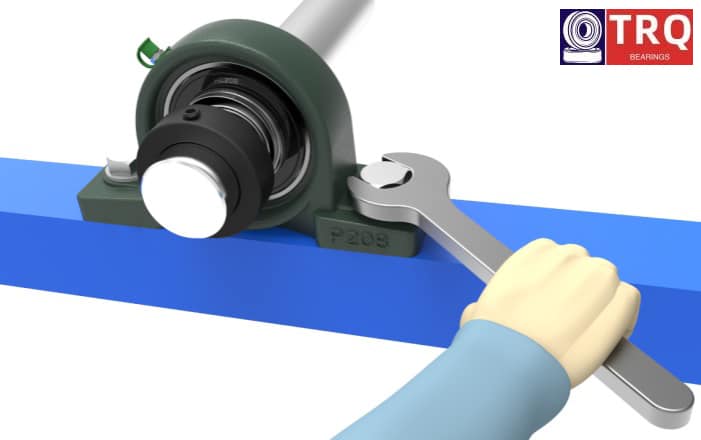

- Tighten the Set Screws: Tighten the set screws according to the recommended torque.

- Re-tighten the Bearing Housing: Excessive tightening torque on the bolts may deform the bearing housing. Use the appropriate tightening torque to secure the bolts.

II. Installation of Eccentric Collar pillow block bearing Bearings:

- Note: Eccentric collar products are not recommended for applications where the direction of rotation changes, as this can cause the eccentric collar to loosen. The preparation work for eccentric collar products is the same as for set screw products.

- Install pillow block bearing:

- Avoid using metal objects like hammers to strike the bearing during installation. This is particularly important for bearings with retaining ring seals, as striking the bearing could cause the retaining ring to shift inward and contact the inner seal, leading to friction during operation. This may result in poor rotation or a significant temperature increase, potentially damaging the bearing. If the bearing bore fits tightly with the shaft, it is recommended to use a press to install it by pressing on the inner ring end face.

-

- Pre-tighten the Bearing Housing: Excessive tightening torque on the bolts may deform the bearing housing. Use the appropriate tightening torque to secure the bolts. TRQ recommends using washers with the bolts when installing the bearing housing, as using bolts alone may damage the bearing housing.

-

- Install the Eccentric Collar: Fit the eccentric collar onto the flange of the inner ring and rotate it manually in the direction of shaft rotation to temporarily tighten it.

-

- Install the Eccentric Collar: Fit the eccentric collar onto the flange of the inner ring and rotate it manually in the direction of shaft rotation to temporarily tighten it.

-

- Tighten the Eccentric Collar: Tighten the set screws on the eccentric collar to the shaft. The recommended tightening torque can be found in the TRQ product manual.

-

- Re-tighten the Bearing Housing: Excessive tightening torque on the bolts may deform the bearing housing. Use the appropriate tightening torque to secure the bolts.

-

- Avoid using metal objects like hammers to strike the bearing during installation. This is particularly important for bearings with retaining ring seals, as striking the bearing could cause the retaining ring to shift inward and contact the inner seal, leading to friction during operation. This may result in poor rotation or a significant temperature increase, potentially damaging the bearing. If the bearing bore fits tightly with the shaft, it is recommended to use a press to install it by pressing on the inner ring end face.

- Install pillow block bearing:

- III. Installation of Adapter Sleeve Mounted Bearings:

- Note: Adapter sleeve mounted bearings are ideal for applications subjected to impact or vibration loads, as there is no risk of the shaft and inner ring becoming loose. However, these bearings are not suitable for high axial load applications. The preparation work for adapter sleeve products is the same as for set screw products.

-

- Install the pillow block bearings: Place the tapered bore mounted bearing onto the adapter sleeve.

-

- Pre-tighten the Bearing Housing: Excessive tightening torque on the bolts may deform the bearing housing. Use the appropriate tightening torque to secure the bolts. TRQ recommends using washers with the bolts when installing the bearing housing, as using bolts alone may damage the bearing housing.

-

- Install the Adapter Sleeve: Gently tap the surface of the sleeve until the bearing and sleeve are properly engaged.

-

- Install the Sleeve Washer and Nut: Insert the washer and hand-tighten the nut.

-

- Tighten the Sleeve Nut: Using a tool (or a screwdriver if no tool is available), place it in the slot on the nut and tap it with a hammer. Stop hammering once the nut has rotated 60 to 90 degrees. Note: Be careful not to strike the retaining ring and avoid over-tightening the nut, as this can deform the inner ring, causing overheating and seizing.

-

- Secure the Nut: Bend the tab on the washer’s edge to engage the slot on the nut, preventing the nut from loosening. Note: Do not loosen the nut backward to align the tab with the slot; instead, tighten the nut further to achieve alignment.

-

- Re-tighten the Bearing Housing: Excessive tightening torque on the bolts may deform the bearing housing. Use the appropriate tightening torque to secure the bolts.

-

-

-

- Note: Adapter sleeve mounted bearings are ideal for applications subjected to impact or vibration loads, as there is no risk of the shaft and inner ring becoming loose. However, these bearings are not suitable for high axial load applications. The preparation work for adapter sleeve products is the same as for set screw products.

IV. Installation of End Cap Mounted Bearings:

- The preparation, bearing installation onto the shaft, and bearing housing installation are similar to standard products.

- Apply Grease: To enhance dust and water resistance, fill the internal rubber seal lips and the internal space of the end cap with grease, occupying two-thirds of the space.

- Install the pillow block bearing: Slide one end cap, filled with grease, onto the shaft, then install the mounted bearing (using the same method as standard products). It is recommended to chamfer the shaft end to avoid damaging the rubber seal lips on the end cap.

- Install the First End Cap: Press the end cap onto the bearing housing. Note: Do not strike the end cap surface directly with a hammer. Instead, use a plastic or wooden block to tap the circumference of the end cap at 45-degree intervals. Do not strike the same position repeatedly; tap around the entire end cap until it is securely installed onto the bearing housing.

- Install the Second End Cap: Note: Do not strike the end cap surface directly with a hammer. Instead, use a plastic or wooden block to tap the circumference of the end cap at 45-degree intervals. Do not strike the same position repeatedly; tap around the entire end cap until it is securely installed onto the bearing housing.

If you encounter any issues during use, please contact me via email at sales@trqbearings.com. I also welcome your feedback and suggestions to help us improve. I look forward to our conversation.

yghfgfgdfvyjyukjaesrthgjhk